Choose any combination of wall, floor, and roof systems to suit your style and fit your budget. Choose a framing style based on your desire for more visible natural wood, or one that allows brighter painted surfaces. Like the exterior of our homes, the interior of your home can be designed to have a more traditional or contemporary style based on your framing style choices. All of our framing systems meet or exceed the International Energy Conservation Codes (IECC) for the coldest regions of the US, including Alaska! We will work with you to decide which framing system best fits your taste and budget.

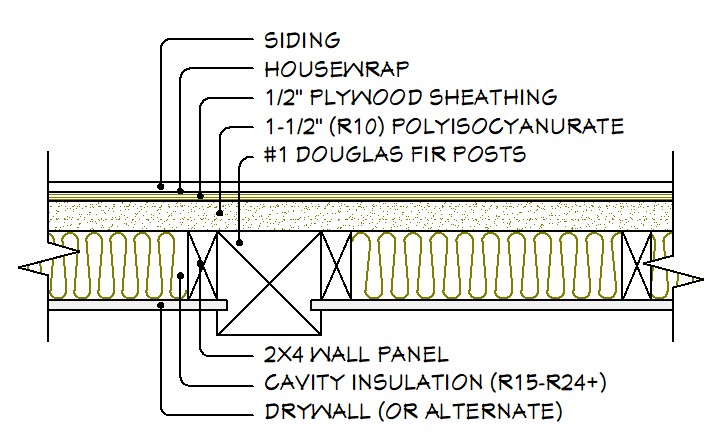

Our energy-efficient wall systems combine the ease of conventional framing with the structural and aesthetic benefits of post and beam. Our 2x4 pre-framed wall panels provide a solid nailbase for siding, trim, cabinets, etc. The wall system also provides a space where plumbing and electrical components can be easily installed. For the exterior walls, a groove is cut into the beams to accept drywall, preventing gapping as the beams expand and contract with changes in humidity. The exterior walls are wrapped in a layer of rigid insulation that prevents thermal bridging, increasing the whole wall's performance. The insulation within the wall cavity can be anything from fiberglass to spray foam, and typically provides a combined value of R-25 to R-32+ (meets or exceeds the IECC energy codes for all climate zones in the US, including Alaska). Optional higher R-Value options are available, please call to discuss.

Our unique system combines the benefits of open cavity framing and the comfort of a complete insulation wrap around the outside of the framing. For a comparison of our wall system to a conventionally framed wall and a stress skin wall system scroll down.

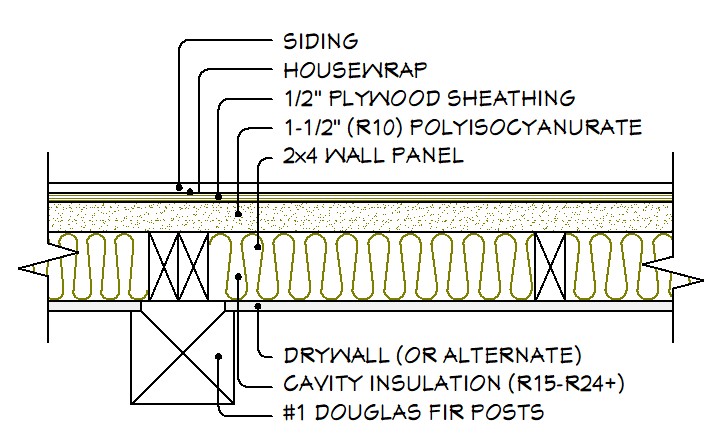

Our unique wall system takes advantage of the ease of conventional framing along with the structural and aesthetic benefits of post and beam. Electrical wires and plumbing can be installed in a way that is familiar to contractors, saving you money.

A groove cut into the posts and beams to accept drywall eliminates the problem of gaps as the wood beams expand and contract with seasonal fluctuations in humidity. An airtight layer of Styrofoam insulation together with housewrap around all wall sections significantly reduces air infiltration and helps to deaden noise. Through the use of the highest quality materials, the Habitat Post & Beam wall system achieves an R-value of 25 to 32+. *The graphic will be updated, but shows our older 1" of exterior XPS insulation as compared to our current 1-1/2" foil-faced polyisocyanurate.

This framing system has a more traditional look, as most of the posts and beams are exposed to the interior. You may opt to include knee braces for the exterior wall (the angled piece shown in the picture to the left). Other than having more of the posts and beams exposed, the specifications for this wall system are the same as our standard wall system above. *The graphic will be updated, but shows our older 1" of exterior XPS insulation as compared to our current 1-1/2" foil-faced polyisocyanurate.

2x4s 16” on center with 1-1/2” foil-faced polyisocyanurate (R 9.8 continuous) insulation with 1/2" CDX plywood sheathing (staggered joints), is included for on-site application to wrap the exterior walls and post and beam frame. Factory rough openings are provided for exterior windows and doors. Housewrap air infiltration barrier provided for exterior coverage. With owner/contractor supplied cavity insulation (spray foam, cellulose, high-density fiberglass, etc.), this wall is designed to significantly outperform typical 2x6 wall construction.

Our wall system is designed to outperform typical conventional 2x6 wall construction. Dow® Styrofoam has an excellent pamphlet* that is available on the Web showing the benefits of using Styrofoam on the exterior of a wall, as we do with our wall system. They summarize with, "Compared to walls consisting of OSB and batt insulation, walls that incorporate Styrofoam brand insulation deliver improved insulation, reduced air infiltration and greater energy savings," and "Styrofoam brand insulation delivers superior insulation and moisture resistance. It's also Energy Star-approved, ensuring efficient performance."

There are many variables to take into account when determining the total performance of any wall system. The three main factors that are typically considered are the R-value, condensation control and air infiltration.

The total R-value of our wall system is higher than that of a conventional 2x6 wall and provides a tighter seal than a 2x6 wall. In addition, our continuous layer of exterior insulation helps reduce thermal bridging (heat loss at all the framing lumber due to wood having a low R-value).

With the Habitat wall system, all of the framing materials are covered by a layer of continuous foam insulation, which performs much better than conventional 2x6 walls.

Whether you are in a hot, cold or changing climate, moisture control is very important with all wall systems. Condensation can form inside of a wall, potentially leading to mold growth and wood rot. With our wall system, the continuous exterior foam insulation becomes a moisture barrier that has a higher surface temperature, resulting in a decreased chance of condensation.

Reducing air infiltration is extremely important so that your home is both energy efficient and draft free. The efficiency of a home drops significantly if it is not both well insulated and relatively airtight. This effect is analogous to going outside on a cold and windy day with just a wool sweater. The wind will go through the sweater and will make you cold. If you had just a windbreaker without a sweater, you would be cold. It would take the combination of both a windbreaker and a thick sweater to keep you warm. A house is the same in that you need to keep it reasonably airtight (windbreaker) and well insulated (sweater) to keep it warm inside.

Our wall system has many benefits compared to stress skin panels. There are many variations on this type of wall panel and many different terms for similar products (stress skin, structural insulated panel, foam core, sandwich panel, etc.). Most of the systems consist of two outer skins (typically oriented strand board) and one inner core of insulating material to form a monolithic unit. For ease of explanation we are going to use the term "stress skins" for comparison to our wall system.

Stress skin panels look like they are a complete and easy solution for use as a wall system. Unfortunately, there is a lot more to a wall system than just insulation and ease of installation.

Most stress skin manufacturers typically advertise similar R-values to both our wall system Stress skins are available in varying thicknesses and types of foam core, resulting in a wide range of R-values. Higher R-values can be specified, but that may not be the best use of additional expense (you can increase R-values for our walls as well). You may be able to more effectively increase thermal performance of your home and make it more comfortable by putting the money into areas where more heat is lost, such as additional roof insulation or higher quality windows.

Both our wall system and stress skin panels handle condensation very effectively by providing a complete thermal break from the framing, resulting in less chance of condensation compared to conventionally framed wall systems.

Both our wall system and stress skin panels do not allow as much air leakage (drafts) as a conventionally framed wall system. Our wall is built in layers, so joints are staggered. With stress skin panels, joints line up through the entire panel. If the manufacturer uses a poor sealing technique, or if the installer does not follow the directions closely and the seal between the panels fails, major air leakage (drafts) can occur. Some manufacturers may still use OSB board and/or glues that contain formaldehyde, which may outgas as the panels age.

The Habitat wall system provides solid wood studs into which nails can be attached. One of the major issues with most stress skin panels is the lack of solid material to use as a nail base both inside and out (they are filled with foam). The Western Red Cedar Lumber Association specifies that siding and trim nails must penetrate 1 ½" into solid wood, otherwise siding can cup, pulling out the nails and loosening the trim, creating gaps that leave the exterior walls vulnerable to further damage. On the interior of the home there is no solid nail base for attaching weighty items such as upper kitchen cabinets, flat screen TVs and large pictures or other wall hangings.

Installing wiring and plumbing within the Habitat wall system requires no special considerations and can be run like a conventionally framed structure. With most stress skin walls, however, there may be some specific techniques that subcontractors will need to become familiar with. Not all stress skin manufacturers include wiring chases, and if they do all of the wiring must be done through an existing chase, making wiring more time consuming and difficult. All outlets and switches must be in predetermined locations, otherwise insulation must be melted out of the panel to add or change locations, compromising the integrity of the panel’s energy efficient properties and increasing labor costs. Future communication and electrical upgrades can become difficult or impossible. Similar issues arise when plumbing within these walls.

Bugs and rodents have been found to burrow into the expanded polystyrene commonly used in stress skin panels (typically not the polyisocyanurate that we use), compromising integrity and insulation value of the panels and creating a host of other issues. "A few cases have been noted where insects and rodents have tunneled throughout the SIPs" (U.S. Department of Energy, consumer energy information: EREC Briefs).

Because of the familiarity contractors will have with our type of wall system, building using our wall panels is inherently more cost efficient. Stress skin panels themselves are fairly expensive, and you may also pay more for some of your subcontractors. Due to the difficulty of working with stress skin panels (as mentioned above), many contractors bids will be higher. Also, "... The tendency for any subcontractor asked to bid on unfamiliar specs is to throw a high number at the job to cover the unusual." (Building with Structural Insulated Panels (SIPS) by Michael Morley p. 140).

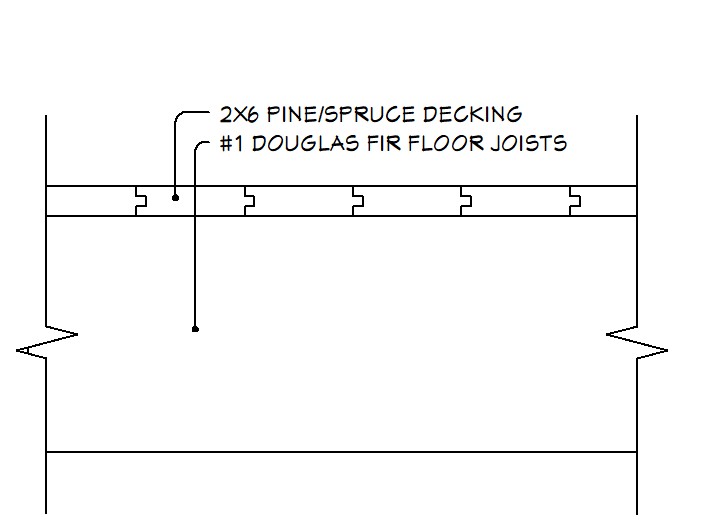

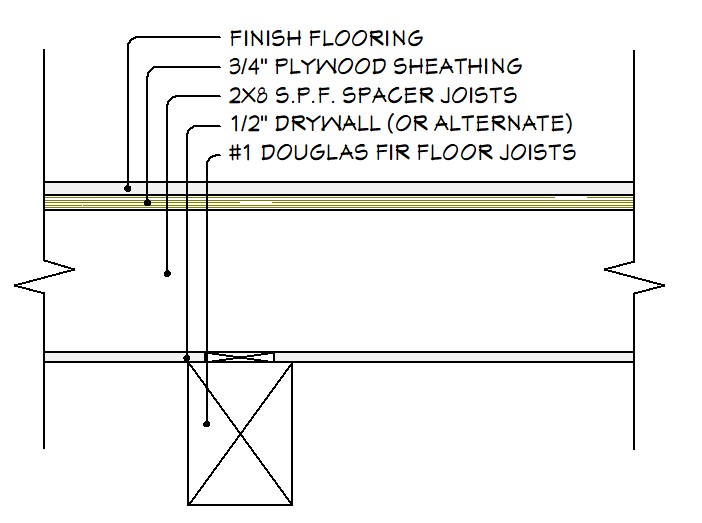

We offer two primary framing systems for the floor between the first level and second level living space (these systems typically cannot be mixed within the same home). Traditional post and beam homes typically have thick boards over timber joists which is a simple system with an all-wood finish (our Beamed Mid-Floor System). This floor system works particularly well if the upper level is lightly used. If the upper level has bedrooms and bathrooms, having a layer of conventional framing over the timber joists can provide a “chase” through which mechanicals can be run (plumbing, electrical, HVAC) and also provide some sound deadening between the levels (our Plaster & Beam Mid-Floor System). The Plaster & Beam Mid-Floor System typically will have drywall placed between the timber joists which provides a brighter finish and brings in more light. As a side note, if you prefer the look of the Beamed Mid-Floor System but need the functionality of conventional framing layer above, you can install thin tongue and groove boards in place of the drywall which changes the name of the system to a Liner & Beam Mid-Floor System.

The Beamed Mid-Floor system offers beautiful exposed beams and floor joists, and the western pine ceiling also provides a finished floor for the level above.

Exposed, select 2x6 kiln-dried tongue and groove western pine plank decking with v-joint to the underside over 6x8 Douglas fir joists 4’ O.C. Southern yellow pine premium laminated beams may be required for longer spans.

The Plaster and Beam Mid-Floor system showcases the ceiling framing, while offering adaptability for recessed lighting, plumbing and added sound control. Use plaster or drywall between the beams to brighten any room.

3/4” tongue and groove Sturd-I-Floor® fir plywood over 2x8 spruce floor joists 16” O.C. with sheetrock shims over 6x8 Douglas fir floor joists 4’ O.C. Sheetrock (drywall) owner/contractor supplied and installed.

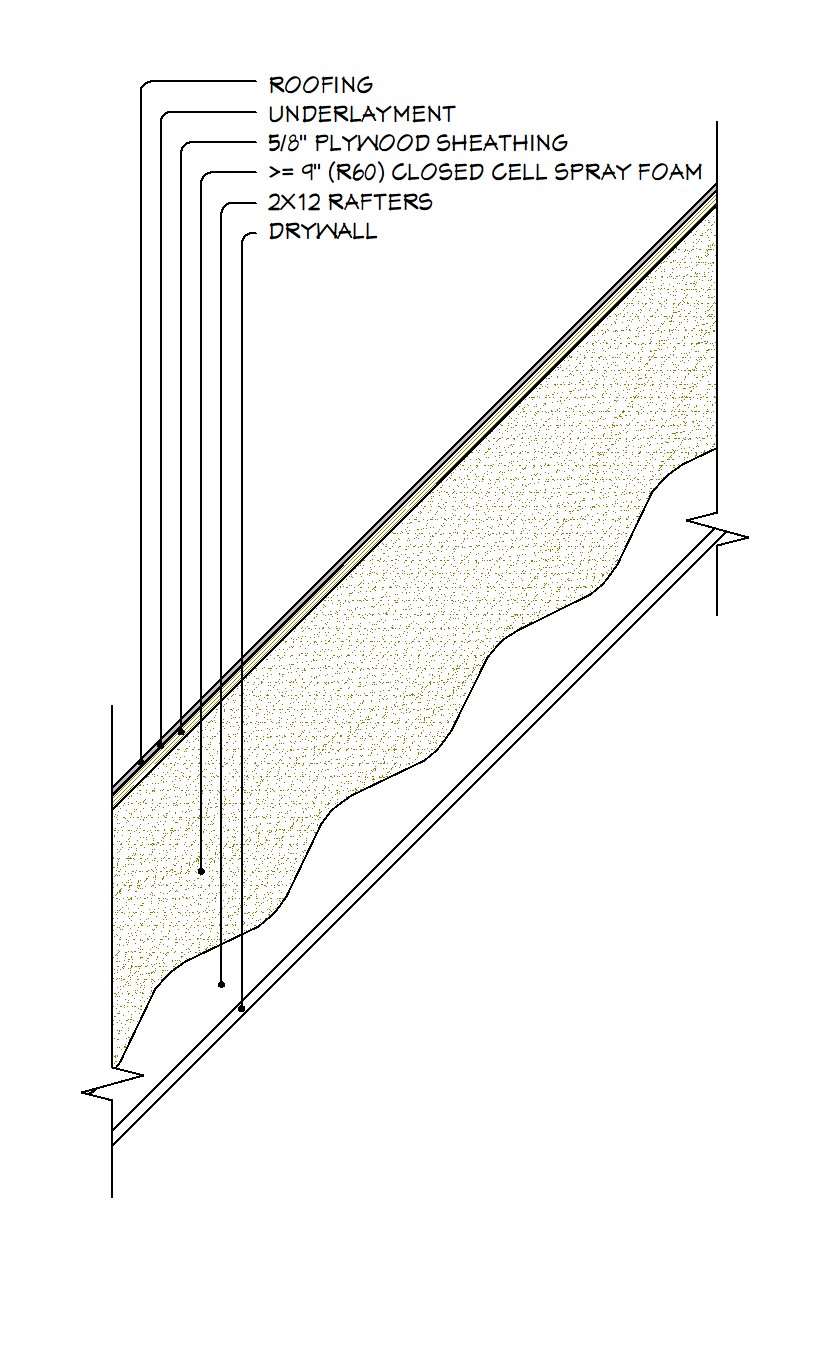

We have a variety of roof framing systems which can be selected based on aesthetics, budget, and practicality. Keep in mind that the roof systems can typically be changed for different areas of the house. Traditional post and beam homes typically have timber rafters with exposed thick boards above the rafters, and the insulation above the framing which provides beautiful and well insulated cathedral ceilings with a lot of exposed wood. If you prefer to have a brighter finish for some or all areas of your home, we can provide conventional rafter framing with timber supports (ridge beams, collar ties, purlins, etc.) and the ceilings can be flat or cathedral. As a third option, you could replace the drywall with thin tongue and groove boards to have an all wood option that doesn’t have timber rafters. All of our roof framing systems meet or exceed the IECC energy codes for all climate zones in the US, including Alaska.

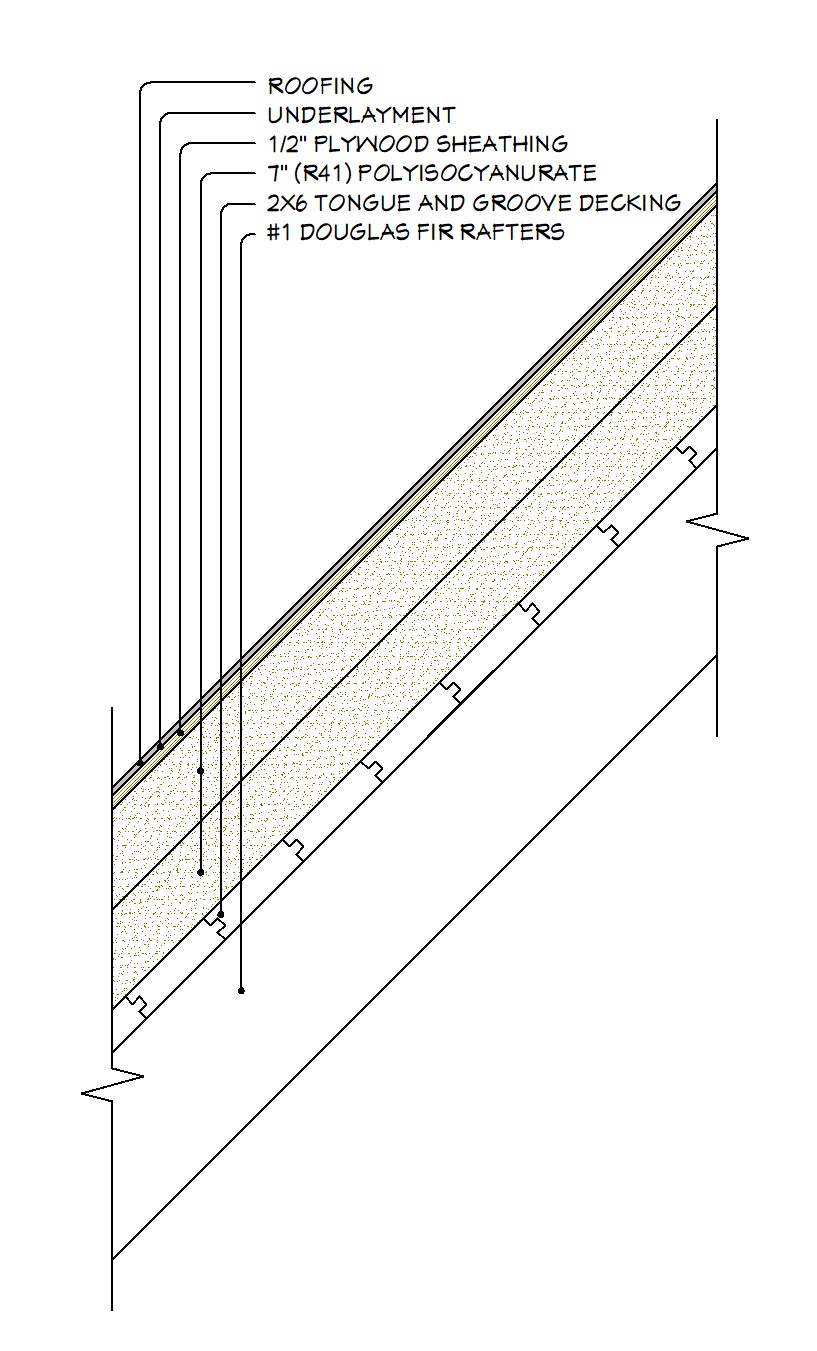

Enhance cathedral ceilings with beautiful cedar or pine decking over Douglas fir rafters. This premium system adds value and energy efficiency.

Exposed ridge beam, collar ties or purlins as required, and 6x8 Douglas fir plate beams. 6x8 Douglas fir rafters and 2x6 kiln-dried tongue and groove Douglas fir, western pine, or western red cedar exposed plank decking with v-joint to the underside. 2” beveled interior finish blocking included for placement above plate beams between rafter bays. 7" rigid urethane insulation (staggered multi-layer) and CDX fir plywood nail base are included over the decking, which meets the IECC energy codes for all climate zones in the US, including Alaska. Higher R-Values can be obtained with an additional layer of insulation.

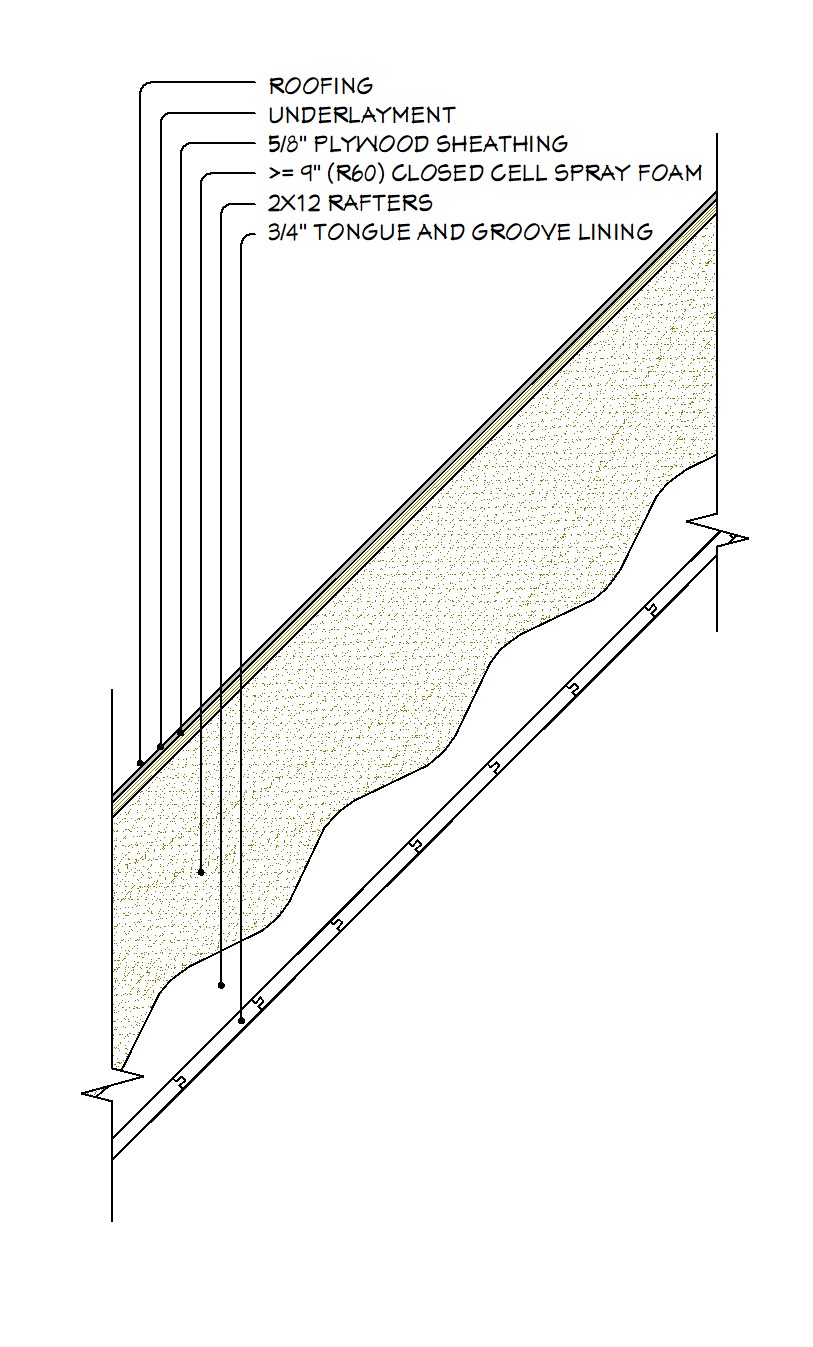

Create an uncluttered all-wood cathedral ceiling more economically than with the Beamed Roof System.

Exposed ridge beam, collar ties or purlins as required, and 6x8 Douglas fir plate beams. Typically 2x12 spruce rafters 2’ O.C. with CDX fir plywood. 1x6 tongue and groove Douglas fir, western pine or western red cedar liner material with v-joint to the underside for interior finish. Fiberglass, spray foam or cellulose insulation owner/contractor supplied and installed. *Newer codes are requiring R-60 for cavity insulation, closed-cell spray foam is the primary option in those cases.

Brighten your rooms with plaster or drywall cathedral ceilings. This is an economical roof system with beautiful exposed support beams.

Exposed ridge beam, collar ties or purlins for cathedral areas as required, and 6x8 Douglas fir plate beams. Typically 2x12 spruce rafters 2’ O.C. and CDX fir plywood. For areas with attic space above (flat ceiling), ceiling joists are included, but the remainder of the ceiling system above is by owner/contractor. Fiberglass, spray foam or cellulose insulation owner/contractor supplied and installed. *Newer codes are requiring R-60 for cavity insulation, closed-cell spray foam is the primary option in those cases.